What are the Advantages and Disadvantages of hydraulic elevators? The elevator is without a doubt one of the most important inventions of the 19th century. In the modern era, it would be difficult to locate a multi-story building without one. And with good cause! Building up rather than out has become possible thanks to the elevator.

Even before the Industrial Revolution, people used elevators. Our modern elevators are considerably different from their older, riskier, rickety relatives. The core concepts underlying elevators haven’t changed all that much, though.

The three primary types of elevators are hydraulic lifts, electric traction lifts, and machine room-free lifts.

Although each of these lift types has advantages and disadvantages of its own, the hydraulic elevator is the most often employed in contemporary culture.

Learn about the Advantages and disadvantages of hydraulic elevators.

Advantages and disadvantages of hydraulic elevators

The benefits and drawbacks of hydraulic elevators, The Pascalian concept of fluid pressure transmission serves as the foundation for the hydraulic system. Fundamentally, control and power are produced by compressing fluids.

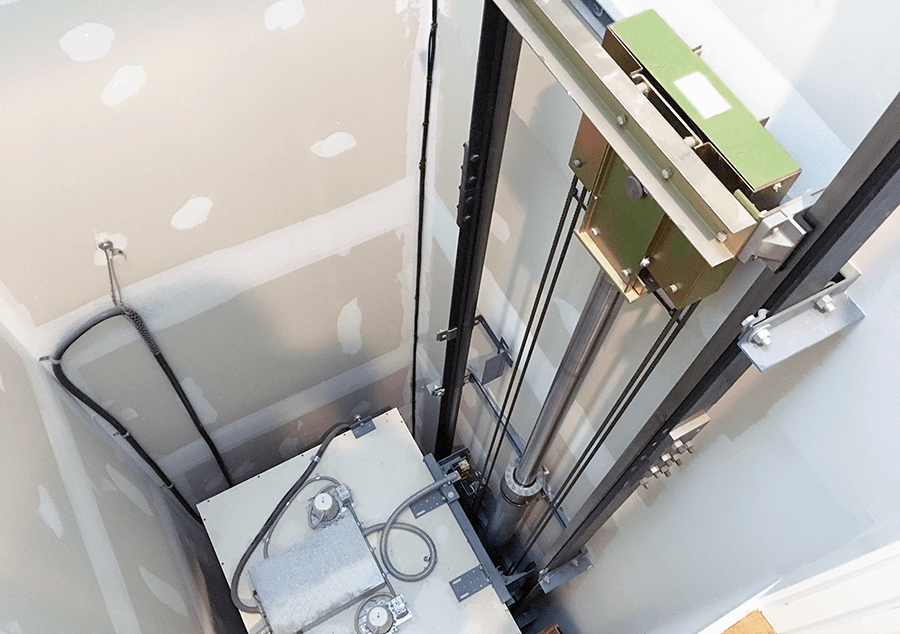

This is how it goes: A pressurized fluid is pushed into a jack lifting system by an electrically powered pump as part of the hydraulic lift’s lifting mechanism. At the lift’s base, a cylinder contains pistons that raise and lower the elevator vehicle.

A hydraulic elevator presses oil into the cylinder with the help of a hydraulic power source to cause the plunger to move directly or indirectly through a wire rope to move the vehicle.

A combined product of mechanical, electricity, electronics, and hydraulics is a hydraulic elevator. It is made up of several largely separate but linked systems, including those for the pump station, the hydraulic system, the guidance system, the automobile, the door, the electrical control system, the safety protection system, etc.

What are the Advantages and Disadvantages of hydraulic elevators?

Advantages and disadvantages of hydraulic elevators Back then, people began to construct dwellings wherever they could. They are finally and unavoidably moving to measure in multi-story apartments and massive skyscrapers, which can be reached by a hydraulic lift.

These buildings lack elevators or lifts, making measurements there uncomfortable. In this post, we’ll go over how hydraulic lifts work and how to use them, and the Advantages and disadvantages of hydraulic elevators.

Advantages of hydraulic elevators

Advantages and disadvantages of hydraulic elevators

Low requirements for civil engineering and maximum shaft usage

Low criteria for the civil structure apply to the hydraulic elevator. It has few requirements on the top floor and simply needs a load-bearing wall instead of a machine room. Additionally, the foundation pit may be quite small. The hydraulic home elevator swiftly took over the majority of the home elevator market due to its low requirements for civil construction.

Extreme security

It is simple to accomplish self-rescue for those who are trapped in the hydraulic elevator because it won’t overspend and lose control. There won’t be any squatting or rushing. As long as the installation is trustworthy, the hydraulic elevator’s safety factor is comparatively high, and the hydraulic elevator has backup power, the mechanical structure’s design will be fair.

Unlike traction elevators, hydraulic elevators don’t rely on belts or ropes to move the elevator. Instead, they apply pressure to an electrical pump to force hydraulic fluid into a cylinder.

What are the disadvantages of hydraulic elevators?

A few drawbacks of hydraulic lifts are as follows:

The lifting’s comparatively modest speed. The maximum speed of a hydraulic lift is 150 feet per minute.

Effective temperature control is crucial because the oil in the piston system might easily overheat.

When the hydraulic oil gets too warm from repeated use, it may release an unpleasant stench.

Hydraulic oil from the pumping system may leak from the elevator’s base and fall to the ground. This might contaminate the groundwater or the soil.

Other elevator methods are typically quieter than hydraulic elevators.

Generally speaking, the lift movement is not as smooth as with other lift methods.

The usage of hydraulic elevators is nevertheless widespread despite these small difficulties.

Certain engine noise is present

The oil pump motor will make some noise when the elevator starts up if the pump station is not separated or close to the hoistway.

Risk of hydraulic oil leakage

The probability of wear and tear after the domestic oil cylinder piston seal ring’s service life increases; if it is not routinely replaced, the hydraulic oil will leak.

High standards for installation and debugging.

According to the installation and commissioning circumstances, which demand more expertise and skill from the installation staff than other elevator platforms, the comfort of the hydraulic elevator should be assessed.

Because of the high population density and tall floor heights in the Chinese market, the early villa elevators were essentially hydraulic elevators.

Advantages and disadvantages of hydraulic elevators

Advantages and disadvantages of hydraulic elevators

The advantages and disadvantages of hydraulic elevators are a tried-and-true technology utilized in buildings with less than 60 feet of travel for more than 50 years. Since they typically have fewer moving parts and lower installation costs than traction elevators, they may be less expensive to maintain and repair. Hydraulic elevators use less energy while waiting and are almost powerless while lowering the cab. In low-use, low-rise scenarios, hydraulic elevators might use less energy than traction elevators. Hydraulic elevators may have a lower overall and operational carbon footprint as a result of these advantages.

While hydraulic elevators can’t operate at the same high speeds as traction elevators, they are adequate for low-rise applications and effectively handle bigger loads.

Hydraulic fluid cylinders had to be extended and inserted into drilled holes in the ground to use hydraulic elevators in the past.

The telescopic jack units that power these completely above-ground hydraulic elevators are fixed to the pit floor and have a 33-12-foot maximum height.

Mechanical and Hydraulic Lifts: Differences and Similarities

complete the talk about the Advantages and disadvantages of hydraulic elevators A mechanical lift and a hydraulic lift differ in several ways:

Mechanical lifts are made to be used indefinitely. There are a set number of cycles per hour and day for hydraulic lifts.

Despite often costing less than mechanical lifts, hydraulic lifts need more regular maintenance than mechanical VRC.

The vertical rise of mechanical lifts is infinite, allowing for lifting to many floor levels. The applications for hydraulic lifts are frequently only two levels and they have a restricted vertical height.

In contrast to hydraulic lifts, which typically have a payload capability of 6,000 lbs Mechanical lifts may raise an almost limitless amount of weight.